We specialize in supplying high-quality replacement parts for the Gyradisc series cone crushers. Our extensive inventory includes, but is not limited to, the following components:

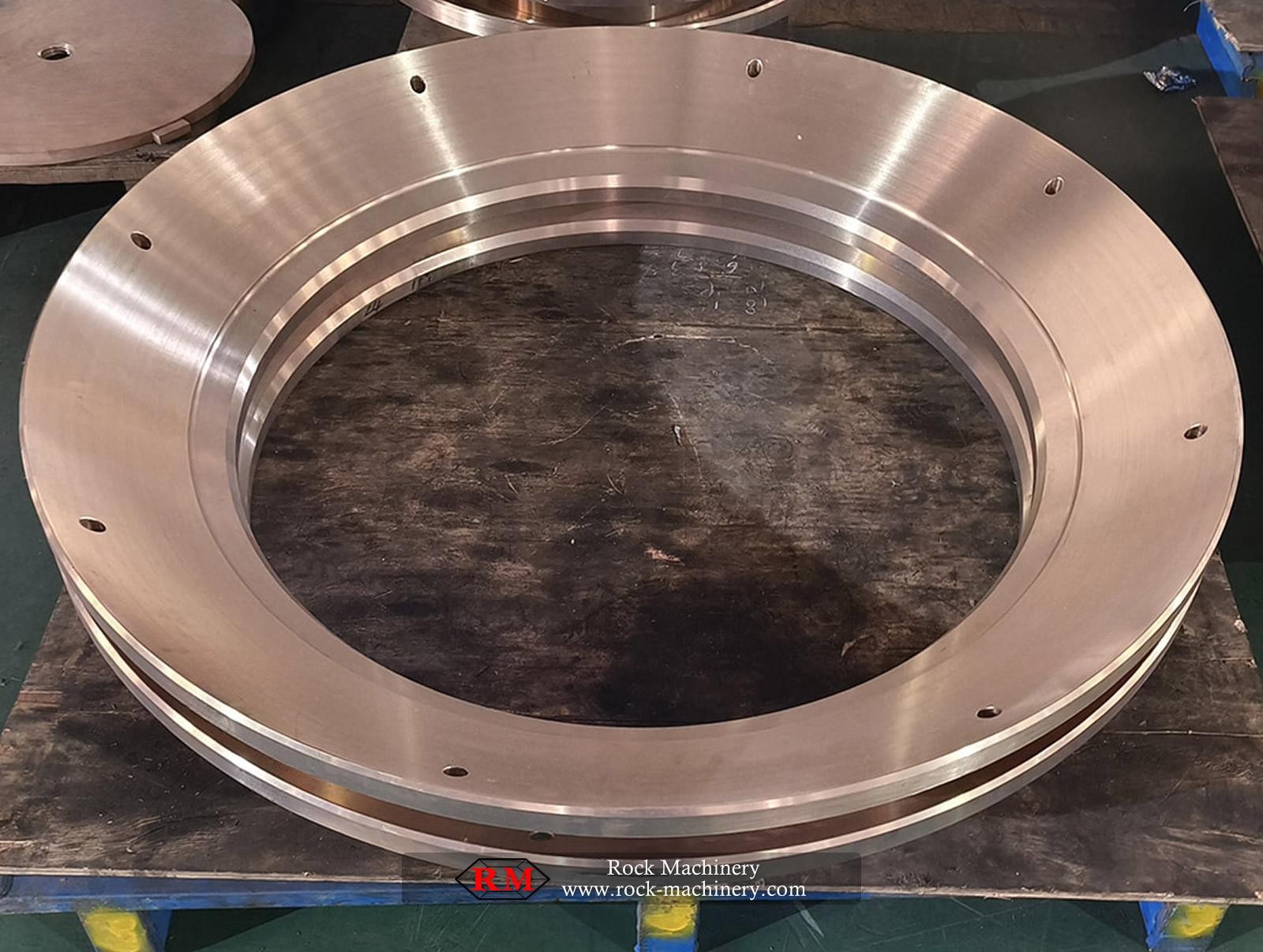

Outer Bushing: Designed to provide optimal support and reduce wear on the crusher's main frame.

Extension Cap: Ensures the crusher's upper section remains secure and aligned during operation.

Socket Liner: A critical component that supports the crusher head and ensures smooth operation.

Inner Bushing: Works in conjunction with the outer bushing to minimize friction and wear.

Lower Liner: Protects the lower section of the crusher from abrasion and impact.

Mantle: The primary crushing surface that interacts with the concave ring to crush the material.

Bowl Liner: Works with the mantle to ensure efficient crushing and long service life.

Eccentric: Drives the gyratory motion of the crusher head, essential for the crushing process.

Locking Nut: Secures the mantle and other components in place, ensuring stability during operation.

Concave Ring: The stationary crushing surface that works with the mantle to crush the material.

Gear and Pinion: These components drive the crusher's eccentric, ensuring smooth and reliable operation.

The Gyradisc cone crusher is specifically designed and built to produce large quantities of manufactured sand to high standards. While its mechanical principles are based on the Symons cone crusher to ensure high reliability, the crushing principle of the Gyradisc is unique and differs completely from other cone/gyratory crushers.

Key characteristics of the Gyradisc cone crusher include:

Rotating Feed Distributor: Ensures an even distribution of material into the crushing cavity, optimizing the crushing process.

Spring Loaded Tramp Release: Protects the crusher from damage caused by uncrushable material by allowing the tramp to release and then return to its original position.

Hydraulic Operation: Provides easy adjustment, clamping, and clearing, enhancing the crusher's operational efficiency.

Balanced Design: Ensures smooth operation and reduces vibration, leading to longer component life.

Pressure Lubrication System: Maintains optimal lubrication of all moving parts, reducing wear and extending the crusher's lifespan.

Precision Made Crushing Liners: Designed for maximum efficiency and durability, these liners ensure consistent performance and reduced downtime.

Our parts are manufactured to meet or exceed the original specifications, ensuring that your Gyradisc cone crusher operates at peak performance. Whether you need a single component or a complete set of parts, we are here to support your crushing operations with reliable and high-quality solutions.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD