Modular, Non-Welded Frame Construction: Offers the highest possible fatigue strength, excellent reliability, and numerous mounting possibilities.

Premium Cast Steel Components: Ensures durability and long service life.

Spherical Roller Bearings: Provide high crusher availability and cost-efficient crushing.

Repairable Construction: Crushers can be rebuilt or repaired after many years of operation.

Optimized Cavity Design: Ensures minimum blockage and eliminates unnecessary height, enhancing performance.

Aggressive Kinematics: Large eccentric throw and steep toggle plate angle magnify the effective stroke at the crusher discharge.

Right Jaws for Applications: Various jaw types and manganese steel alloys are optimized for different applications, maximizing throughput and minimizing operating costs.

Fast and Easy Setting Adjustment: Hydraulic setting adjustment system allows quick changes, even while the crusher is running.

Durable Bearings: Higher load-bearing capacity and effective lubrication result in longer bearing life.

Integral Motor Base: Reduces space requirements and maintenance costs.

Compact and Service-Friendly Flywheel Guards: Protect operators and allow easy access for service.

Wide Range of Applications: Suitable for stationary and mobile applications, including aggregate production, mining (surface and underground), and recycling.

Custom Feed Chutes: Designed to guide feed effectively into the crusher cavity and can be removed for maintenance.

Surface Installations: Ideal for quarries, gravel pits, and recycling plants due to their size, simplicity, and productivity.

Underground Installations: Easy to transport and assemble underground, with components that can be handled individually.

Leader in Mobile Crushing: Pioneered the development of track-mounted, fully mobile crushing plants.

Flexibility and Transportability: Offers considerable benefits, including reduced quarry traffic and lower transport costs.

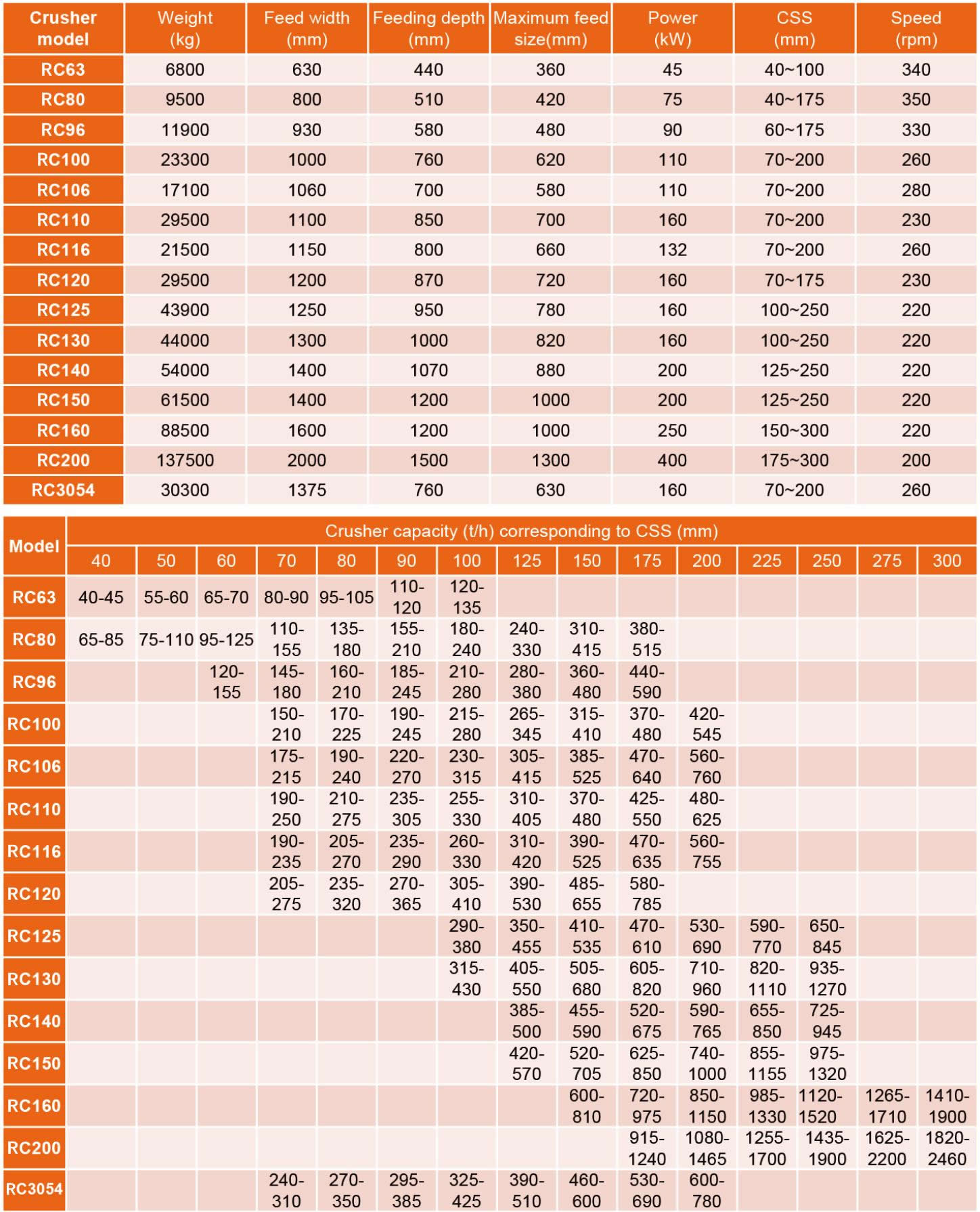

Dimensions and Weights: Detailed specifications for various models (RC80, RC100, RC96, RC106, RC116, RC3054, RC120, RC125, RC140, RC150, RC160, RC200) including feed opening width and depth, power, speed, and product size.

Capacities: Indicative product gradation and throughput capacities based on specific feed characteristics.

Automatic Grease Lubrication System: Ensures consistent lubrication.

Protection Plates: Protect the crusher and discharge conveyor belt from damage.

Temperature and Speed Sensors: Monitor crusher performance and integrate with plant automation systems.

Overall, the Nordberg C Series jaw crushers are designed to deliver high performance, reliability, and cost efficiency across a wide range of crushing applications, making them a preferred choice in the industry.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD