a. When the spiral gravel washer is delivered, the user should immediately check whether each component is complete and whether there is any damage. Only after confirming that the machine is complete and intact can installation be carried out.

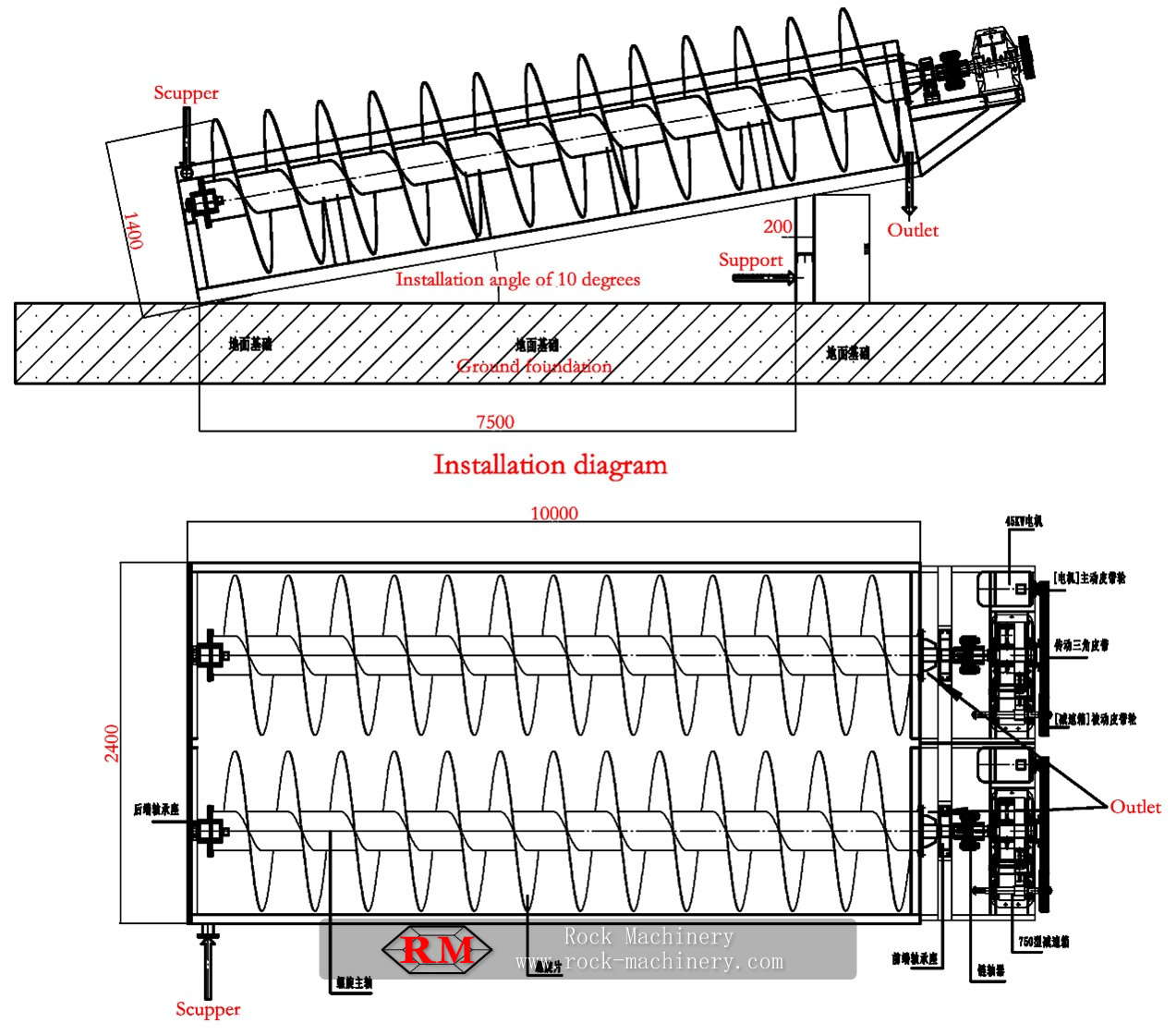

b. The user should design the stone washing machine's foundation construction drawings according to the circumstances on site and install the stone washing machine stably on the solid reinforced concrete foundation.

c. During installation of the machine, it is necessary to ensure that the machine is installed at an angle of inclination as required by the installation diagram.

d. The motor is mounted on rails to allow adjustment of the belt tension, and the belt pulley should be kept parallel with the motor pulley during installation.

e. After the above adjustments, the rotor plate was rotated a few times to check for stuck. The machine is now installed here.

f. The machine must run in good lubrication environment. Must add butter and lubricating oil before running for the first time in power. And check and add every week as shown.

g. Electrical control cabinets as well as motors and wiring must be properly grounded, and it is forbidden to have electrical leakage in the electrical control cabinets, motors, and wiring.

a. Following are the guidelines for safe operation, but it should not be expected to cover every specific situation that may arise.

b. Safety is paramount for all personnel. The user is ultimately responsible for the safe operation of the equipment and for his own benefit, should prepare the most appropriate and reliable rules according to law, industrial regulations and the specific conditions of the industrial workplace before using the equipment.

c. Be sure you have read this manual and have been instructed in safe operation before operating or servicing machine. Do not let untrained people operate the machine.

d. Do not wear loose clothing around machinery.

e. Wear appropriate protective gear.

f. Operators may walk only in safety aisles in the plant area.

g. safety channel should be kept clean, intact and clear.

h. Do not enter other work areas unless authorized to do so.

i. Read and observe all danger signs on equipment.

j. Do not start equipment until you verify that all personnel are clear.

k. Do not touch the transmission parts of the unit during the operation. If any abnormality is found, the unit operation should be stopped immediately.

l. The switch cabinet as well as the motor must be properly grounded, and the power supply must be cut off before the equipment is repaired, and the equipment can be maintained and repaired.

m. Before equipment start-up, it is necessary to confirm the equipment is free of load under safe conditions before start-up.

n. Watch the equipment operation all the time, and do not approach it during operation.

o. Strictly working around the machine while it is running. Touching/adjusting/cleaning/inspecting the machine by hand.

p. Electrical control cabinets as well as motors and wiring must be properly grounded, and it is forbidden to have electrical leakage in the electrical control cabinets, motors, and wiring.

a. Operators must study the equipment manual carefully before operating or maintaining the equipment, and must undergo safety operation training before taking up the job.

b. Equipment requiring service is to be serviced using qualified replacement parts and tools.

c. When adding lubricant, use the lubricant recommended in the instructions.

d. Before overhauling the equipment, the power supply must be cut off, and the safety warning sign must be hung up before the equipment can be maintained and overhauled. After the maintenance and overhaul of the equipment are completed, the safety facilities of the equipment must be improved, the hanging safety warning sign must be removed, and after checking that all the safety is complete, the work can be carried out.

e. Do not perform lubrication, cleaning, repairs, and maintenance work while the equipment is running or in operation.

f. When starting up the equipment, start the equipment after making sure that all safety precautions are in place. Watch the equipment operation at all times.

a. The feed must be kept uniform by feeding device evenly, do not feed directly, also may be fed with a belt conveyor, and the feeding must not be excessive or deficient.

b. After the motor is started, the machine should run smoothly, without abnormal vibration.

c. Bearing temperature rise do not exceed 35 degree.

d. 2-4 hours of idling, After the test, check the connections for any looseness and adjust them.

e. Load operation test can only be conducted on the basis of a successful empty load operation test.

f. The machine should run smoothly, no abnormal vibrations.

g. The bearing temperature increase does not exceed 45 degrees.

h. No dust should enter the sealed areas.

i. when the production line is down, the stone washing machine must run for another 5-10 minutes until there is no more material in the slot body. Then it can be stopped.

a. This product is a washing, classifying, dewatering machine specially designed and manufactured for sand units such as gravel, quartz sand, suitable for construction units such as quarries, construction sites, hydropower station dams, and road construction. The optimized sealing structure, adjustable overflow weir plate, and simple and durable transmission structure can ensure the high efficiency and durability of the product. However, the output of the washing machine will be affected when the content of mud and dust in the raw material is too high.

a. Stone washing machine main shaft.

b. Stone washing machine wheel.

c. Reducer and pulley wheel.

d. Transmission triangle

e. Transmission motor.

f. Stone washing machine body.

g. Stone washing machine leaves.

h. Frame.

a. The series of stone washing machines work in a spiral rotating motion with the working principle of; through the motor driving the belt pulley and belt, through the reducer, the washing stone wheel of the wheel-type stone washing machine is rotated, and the reducer is connected to the washing stone wheel through a coupling to drive the washing stone wheel to rotate. The washing stone wheel is rotated in a clockwise direction. The cleaned stone is cleaned through the spiral blade, and the stone is brought out of the water tank body at the lower end to the upper end for dehydration and discharging. The waste water flows out through the overflow slot, and the mud and sand are discharged from the feeding slot of the stone washing machine during the rotation of the stone washing wheel. With the continuous rotation of the motor, the washing stone wheel is driven to work in a cycle.

a. Stone washing machine leaves.

b. Arc Card

| Model | 2XS-600 | 2XS-800 | 2XS-1000 | 2XS-1200 |

| Helix Diameter(mm) | 600 | 800 | 1000 | 1200 |

| Trough Length(mm) | 5500 | 6500 | 7500 | 8500 |

| Wash size(mm) | ≤50 | ≤65 | ≤65 | ≤65 |

| Production Capacity(T/H) | 50-100 | 100-150 | 150-200 | 200-300 |

| RPM | 40 | 36 | 30 | 26 |

| Motor power(KW) | 2×18.5 | 2×22 | 2×30 | 2×37 |

| Water Consumption(T/H) | 150-180 | 110-135 | 100-150 | 200-250 |

| Machine Weight(KG) | 135000 | 155000 | 195000 | 230000 |

| Dimensions(Long, Width, Height) | 6500×1500×1350 | 7500×2000×1600 | 8500×2200×1600 | 9500×2500×1600 |

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD