We are proud to offer an extensive range of high-quality replacement parts for Minyu cone crushers. Our inventory includes critical components such as seat liners, concaves, eccentric bushings, mantles, and frame bushings. Each part is meticulously designed to meet the exact specifications of Minyu cone crushers, ensuring optimal performance, durability, and compatibility. Below is a detailed description of the parts we supply and their significance in maintaining the crusher's efficiency.

The seat liner is a crucial component that provides a stable base for the crusher's moving parts. It ensures proper alignment and reduces wear and tear on other components, contributing to the crusher's longevity and consistent performance.

The concave is a key wear part that forms the crushing chamber along with the mantle. It is designed to withstand high-impact forces and abrasion, ensuring efficient crushing of materials. Our concaves are engineered for quick and easy replacement, minimizing downtime during maintenance.

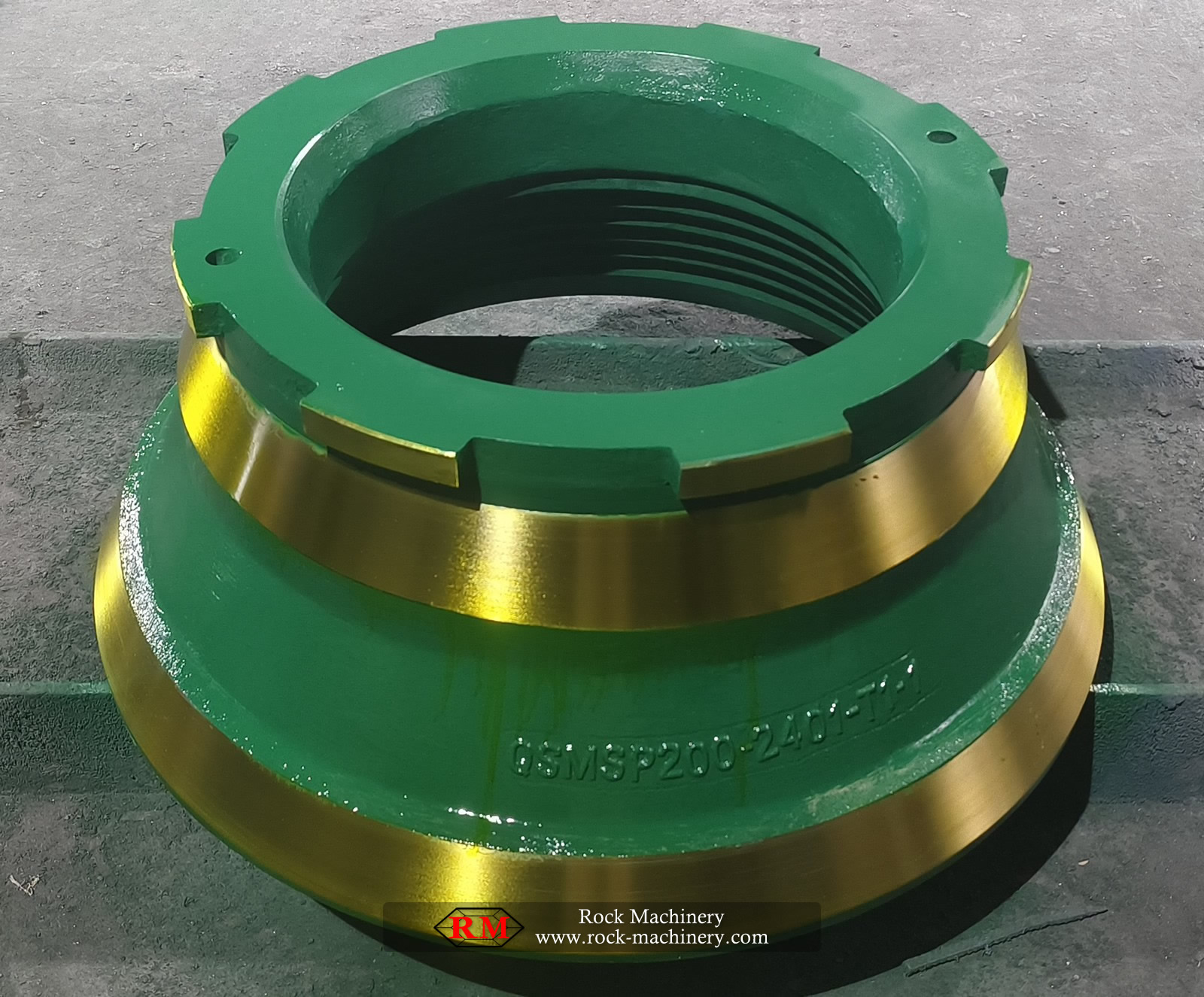

The eccentric bushing plays a vital role in the crusher's gyratory motion, enabling the mantle to perform its crushing action. Our bushings are manufactured to precise tolerances, ensuring smooth operation and reducing the risk of mechanical failure.

The mantle is the primary crushing surface that interacts with the concave to break down materials. Our mantles are made from high-quality materials to resist wear and maintain their shape over time, ensuring consistent product sizing and crushing efficiency.

The frame bushing supports the crusher's main shaft and helps maintain its alignment during operation. Our frame bushings are designed to handle heavy loads and reduce friction, contributing to the crusher's overall reliability and performance.

The Pinion Shaft Assembly is a precision-engineered power transmission component in Minyu cone crushers. It serves as the primary interface between the motor drive system and the crushing mechanism, converting rotational input into the gyratory motion required for rock crushing.

In addition to supplying high-quality parts, we would like to highlight the advanced features of Minyu cone crushers that make them stand out in the industry:

Minyu cone crushers are designed to deliver high-capacity output with excellent product shape and uniform sizing. This ensures that the crushed material meets the highest quality standards, making it suitable for a wide range of applications.

The crusher frame is stress-relieved and reinforced at high-stress points, providing exceptional strength and durability. This design minimizes the risk of frame deformation or failure, even under heavy loads, ensuring long-term reliability.

Minyu cone crushers feature a hydraulic adjustment system that allows for quick and precise setting changes, enhancing operational flexibility. Hydraulic clearing is standard on SP Cone Crushers, with release cylinders that facilitate rapid clearing of the crushing chamber, reducing downtime during maintenance.

The concave design eliminates the need for filling material, enabling quick and hassle-free replacement. This feature significantly reduces maintenance time and improves operational efficiency.

In the event of an overload, the crusher is equipped with an automatic restoration system that maintains the discharge opening and ensures steady production. This feature protects the crusher from damage and maintains consistent performance.

SP Cone Crushers are equipped with a high-capacity, externally mounted lubrication pump, oil tank, and oil filtering system. Safety mechanisms such as high oil temperature shut-down, low oil flow shut-downs, and an oil flow gauge are integrated to protect the crusher. An optional heat exchanger is also available to maintain optimal operating temperatures.

The crusher's higher eccentric height increases the crushing ratio and improves crushing efficiency, allowing for more effective processing of materials and higher productivity.

The concave is securely locked to the top cell from above, ensuring stable fixation and easy exchange. This design enhances the crusher's reliability and simplifies maintenance procedures.

Minyu cone crushers operate at a higher rotation speed of up to 800 rpm, which boosts crushing capacity and throughput, making them ideal for high-volume operations.

The increased height of the mantle and concave improves crushing efficiency by allowing for more effective material processing. This design ensures that the crusher can handle larger feed sizes and produce finer output.

The crusher's increased stroke at the feed opening enhances the crushing ratio and throughput, making it more efficient in processing large volumes of material.

The main frame is constructed to be strong and tidy, ensuring long-term durability. The crusher sheave is designed for high power transmission rates, which extends the service life of the drive device and reduces maintenance requirements.

We are committed to providing our customers with the highest quality parts and exceptional service. Our extensive inventory ensures that we can supply almost all components for Minyu cone crushers, helping you maintain optimal performance and minimize downtime. Whether you need seat liners, concaves, eccentric bushings, mantles, or frame bushings, we have you covered.

For more information about our products or to discuss your specific requirements, please do not hesitate to contact us. Our team of experts is ready to assist you in finding the right solutions for your crushing needs.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD