We specialize in providing high-quality replacement parts for Metso MP Series cone crushers, ensuring optimal performance and longevity for your crushing operations. Our extensive inventory includes, but is not limited to, the following critical components:

Main Frame: The robust main frame is designed to withstand maximum crushing loads, ensuring durability and stability during operation.

Adjustment Ring: This component allows for precise control of the crusher setting, enabling consistent size reduction and efficient operation.

Eccentric: The eccentric assembly is engineered to provide maximum throughput and crushing efficiency, crucial for both coarse and fine crushing applications.

Socket: The socket liner offers maximum head support and multiple oil grooves for full lubrication, ensuring smooth operation and reduced wear.

Head: The head assembly is designed to sustain high crushing loads, with features that reduce head spin and ensure reliable performance.

Feed Plate: Replaceable feed plates distribute incoming feed evenly, protecting the crusher from uneven wear and enhancing overall efficiency.

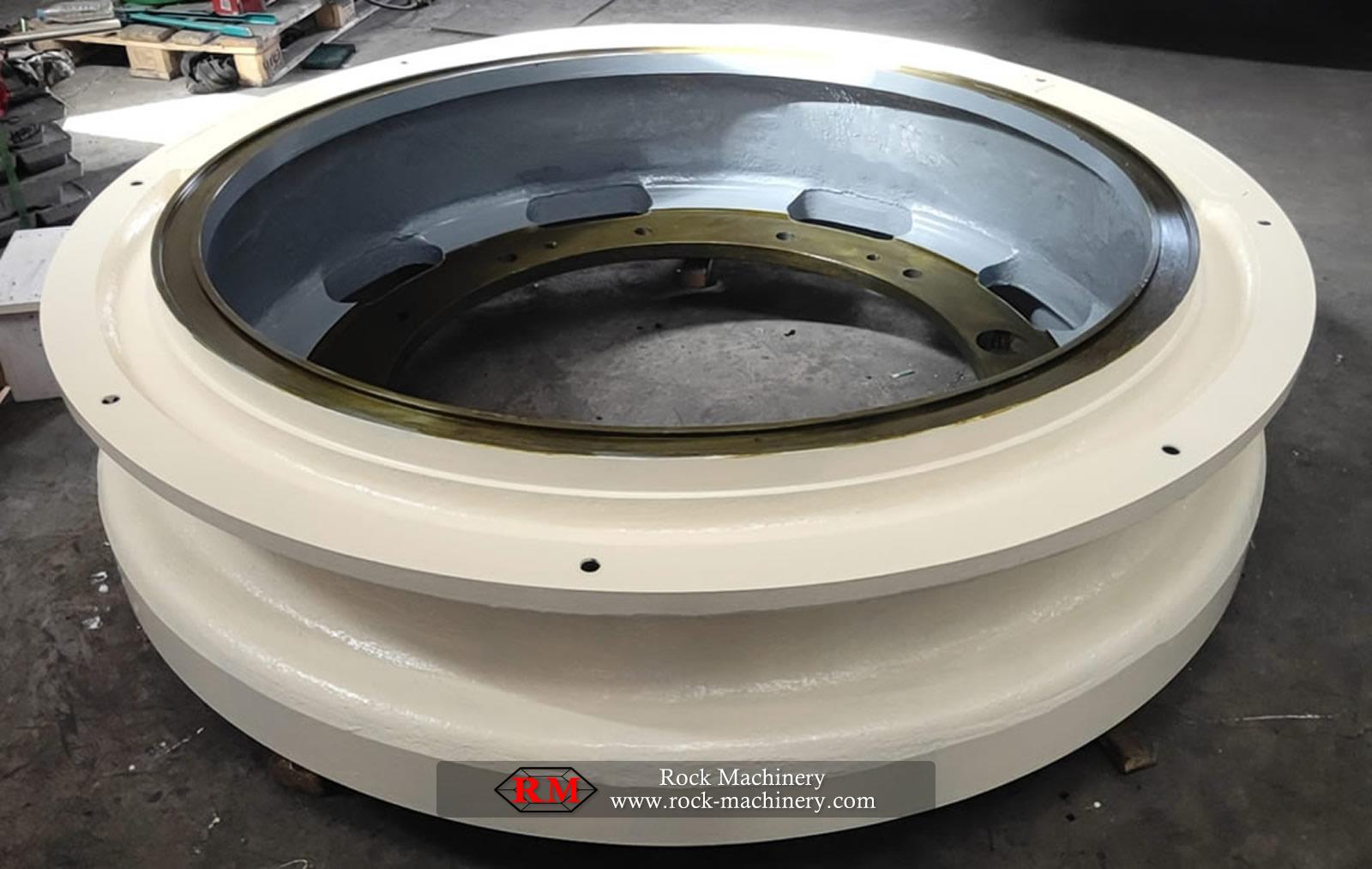

Bowl: The rotating bowl compensates for feed segregation and ensures even wear in the crushing cavity, maintaining consistent crusher settings.

Main Shaft: Forged from high-strength alloy steel, the main shaft distributes oil to various high-performance bearings, ensuring smooth and reliable operation.

Eccentric Bushing: This component supports the eccentric assembly, providing strength and durability for dependable power transmission.

Upper Thrust Bearing: Designed to handle high crushing forces, the upper thrust bearing ensures smooth operation and reduces wear on other components.

Counterweight: The counterweight reduces unbalanced forces created by the rotating eccentric, enhancing the crusher's efficiency and stability.

Socket Liner: This liner provides maximum head support and ensures full lubrication of the gyrating head ball, crucial for maintaining performance.

Head Bushing: The head bushing is uniquely designed to reduce head spin and ensure smooth operation, even under high crushing loads.

Frame Seat Liner: This liner provides extra protection to areas exposed to material passing through the crusher, enhancing durability and performance.

Upper Head Bushing: Designed to reduce head spin, this bushing ensures reliable performance and reduces wear on other components.

Bowl Liner: The bowl liner is designed for even wear and maximum metal utilization, ensuring consistent size reduction and efficient operation.

Mantle: The mantle is crucial for achieving the desired crushing performance, with designs that ensure optimal particle shape and size reduction.

HYD Drive Assy: Responsible for providing precise hydraulic control to optimize crusher performance and protect critical components during operation. It integrates hydraulic power and automation to manage adjustments, overload protection, and operational stability.

The Metso MP Series cone crushers are renowned for their maximum power and superior crushing performance. These crushers are designed to deliver up to twice the capacity per crushing station compared to conventional crushers, making them ideal for secondary and tertiary crushing applications.

High Productivity: The MP Series incorporates advanced process technology to produce the highest crushing force in the industry, ensuring more ore is processed to the same or finer reduction.

Consistent Performance: Features such as hydraulic controls, a rotating bowl, and automatic tramp release ensure consistent performance, even with varying feed conditions.

Adaptability: The MP Series can operate at various speeds and cavity combinations, making it suitable for a wide range of crushing requirements. The ability to use one head for all cavities further enhances its application flexibility.

Reliability: With features like hydraulic cavity clearing and easy setting adjustment, the MP Series minimizes downtime and ensures high availability. Routine maintenance is simplified with user-friendly components.

Ease of Operation: Push-button controls and remote adjustment capabilities make the MP Series easy to operate, while advanced sensors ensure safe and efficient operation.

Simple Maintenance: The MP Series features push-button disassembly and modular components, making routine maintenance straightforward and reducing downtime.

Our parts are designed to meet the exact specifications of Metso MP Series cone crushers, ensuring seamless integration and optimal performance. Whether you need a single component or a complete set of parts, we are committed to providing high-quality solutions that enhance your crushing operations.

For more information on our parts and services, please contact us. We are here to support your needs and ensure your Metso MP Series cone crushers operate at peak efficiency.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD