We specialize in supplying a comprehensive range of high-quality replacement parts for Sandvik CS series cone crushers. Our parts are designed to ensure optimal performance, durability, and reliability, helping you maintain the efficiency of your crushing operations. Below is a detailed overview of the parts we offer and their significance in the operation of Sandvik cone crushers.

Spider Bushing: This critical component supports the spider assembly and ensures smooth operation of the crusher. It is designed to withstand high loads and reduce wear on the spider.

Seal Ring: The seal ring prevents dust and other contaminants from entering the crusher's internal mechanisms, thereby protecting the crusher's longevity and reducing maintenance needs.

Support Ring: This ring provides structural support to the crusher's upper section, ensuring stability during operation.

Arm Shield: The arm shield protects the crusher's arms from wear and tear, extending the life of the crusher's moving parts.

Concave Ring: This ring is crucial for the crushing process, as it forms the crushing surface along with the mantle. It is designed to handle high-impact forces and abrasive materials.

Filler Ring: The filler ring helps maintain the proper alignment and spacing within the crusher, ensuring efficient crushing performance.

Hose: High-quality hoses are essential for the hydraulic system, ensuring smooth and reliable operation of the crusher's adjustment mechanisms.

Mantle: The mantle is one of the most critical wear parts in a cone crusher. It works in conjunction with the concave to crush the material. Our mantles are made from high-quality materials to ensure long-lasting performance.

Wear Plate: Wear plates protect the crusher's body from abrasion and impact, reducing the need for frequent replacements and maintenance.

Topshell: The topshell houses the upper section of the crusher, including the mantle and concave. It is designed for easy access and maintenance.

Boss: The boss is a key component that connects the mainshaft to the crusher's structure, ensuring proper alignment and smooth operation.

Bottom Shell Bushing: This bushing supports the bottom shell and reduces friction, ensuring smooth rotation of the crusher's components.

Foot: The foot provides a stable base for the crusher, ensuring it remains securely in place during operation.

Liner Narrow Arm: This component protects the crusher's arms from wear, extending the life of the crusher's moving parts.

Eccentric Wearing Plate: The eccentric wearing plate is designed to withstand the high forces generated during the crushing process, ensuring long-lasting performance.

Bracket: Brackets provide structural support to various components of the crusher, ensuring stability and reliability.

Liner Pinionshaft Arm: This component protects the pinionshaft arm from wear, ensuring smooth operation of the crusher.

Bottomshell: The bottomshell houses the lower section of the crusher, including the eccentric and mainshaft. It is designed for easy access and maintenance.

Pinion Shaft Housing: This housing protects the pinion shaft and ensures proper alignment, reducing wear and tear on the crusher's components.

Bearing Cover: The bearing cover protects the crusher's bearings from dust and contaminants, ensuring smooth operation and reducing maintenance needs.

Spacer: Spacers are used to maintain proper spacing between components, ensuring efficient operation of the crusher.

Pinion Shaft: The pinion shaft is a critical component that drives the crusher's eccentric, ensuring smooth and reliable operation.

Hub: The hub connects the pinion shaft to the crusher's structure, ensuring proper alignment and smooth operation.

Eccentric: The eccentric is a key component that drives the crusher's crushing action. It is designed to withstand high forces and ensure long-lasting performance.

Ring: Rings are used to maintain proper alignment and spacing within the crusher, ensuring efficient crushing performance.

Key: Keys are used to secure various components of the crusher, ensuring they remain in place during operation.

Eccentric Bushing: The eccentric bushing reduces friction and wear on the crusher's eccentric, ensuring smooth operation.

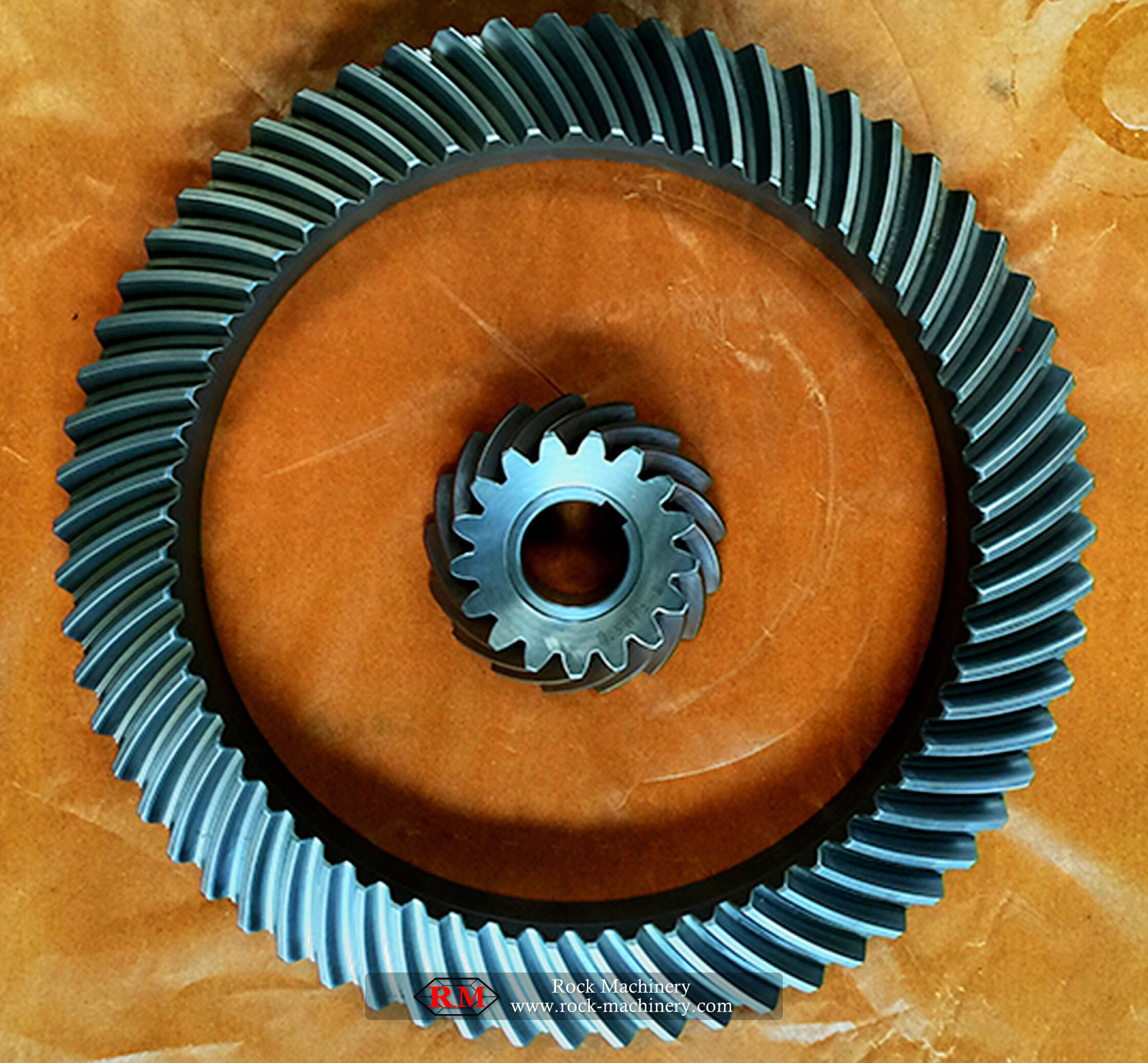

Gear and Pinion: The gear and pinion are critical components that drive the crusher's eccentric, ensuring smooth and reliable operation.

Inner Head Nut: The inner head nut secures the mainshaft in place, ensuring proper alignment and smooth operation.

Mainshaft Sleeve: The mainshaft sleeve protects the mainshaft from wear and tear, ensuring long-lasting performance.

Retaining Ring: Retaining rings are used to secure various components of the crusher, ensuring they remain in place during operation.

Dust Seal Ring: The dust seal ring prevents dust and contaminants from entering the crusher's internal mechanisms, reducing maintenance needs.

Retainer: Retainers are used to secure various components of the crusher, ensuring they remain in place during operation.

Scraper: The scraper removes debris from the crusher's components, ensuring smooth operation and reducing maintenance needs.

Burning Ring: The burning ring is designed to withstand high temperatures, ensuring long-lasting performance in high-heat environments.

Mainshaft: The mainshaft is a critical component that drives the crusher's crushing action. It is designed to withstand high forces and ensure long-lasting performance.

Head Center: The head center supports the mainshaft and ensures proper alignment, reducing wear and tear on the crusher's components.

Seal Ring Inner: The inner seal ring prevents dust and contaminants from entering the crusher's internal mechanisms, reducing maintenance needs.

Locating Bar: The locating bar ensures proper alignment of the crusher's components, ensuring efficient operation.

Gasket: Gaskets are used to create a seal between various components of the crusher, preventing leaks and ensuring smooth operation.

Shim: Shims are used to adjust the spacing between components, ensuring proper alignment and efficient operation.

Dust Collar Inner: The inner dust collar prevents dust and contaminants from entering the crusher's internal mechanisms, reducing maintenance needs.

Hydroset Cylinder: The Hydroset cylinder is a key component of the crusher's hydraulic adjustment system, ensuring smooth and reliable operation.

Hydroset Cylinder Bushing: The Hydroset cylinder bushing reduces friction and wear on the Hydroset cylinder, ensuring long-lasting performance.

Packing Clamp Plate: The packing clamp plate secures the packing in place, ensuring a proper seal and preventing leaks.

Piston Wearing Plate: The piston wearing plate is designed to withstand high forces, ensuring long-lasting performance in the crusher's hydraulic system.

Step Washer: Step washers are used to maintain proper spacing between components, ensuring efficient operation of the crusher.

Mainshaft Step: The mainshaft step ensures proper alignment of the mainshaft, reducing wear and tear on the crusher's components.

Piston: The piston is a key component of the crusher's hydraulic system, ensuring smooth and reliable operation.

Chevron Packing: Chevron packing is used to create a seal in the crusher's hydraulic system, preventing leaks and ensuring smooth operation.

Plug: Plugs are used to seal various openings in the crusher, preventing leaks and ensuring smooth operation.

Hydroset Cylinder Cover: The Hydroset cylinder cover protects the Hydroset cylinder from dust and contaminants, ensuring smooth operation and reducing maintenance needs.

The Sandvik CH series cone crushers are known for their robust design and high performance. These crushers are hydraulically adjusted, allowing for precise control over the crushing process. The combination of high motor power and the CLP (Constant Liner Performance) crushing chambers ensures that these crushers deliver capacities comparable to larger crushers, making them an excellent choice for secondary and tertiary crushing applications.

The CLP crushing chambers offer several advantages, including constant feed acceptance capability, increased output, high-quality product shape, increased liner life, and the lowest total cost of ownership. Additionally, Sandvik cone crushers can be equipped with the ASRi (Automatic Setting Regulation) system, which continuously monitors the crushing load and optimizes crusher performance, ensuring maximum efficiency at all times.

Sandvik cone crushers are highly versatile and can be easily matched to changes in production requirements through the proper selection of crushing chambers and eccentric throws. They are an excellent choice as secondary crushers in combination with jaw or primary gyratory crushers, or in the third or fourth crushing stage. Their built-in versatility allows them to adapt to most production requirements, making them a reliable choice for a wide range of applications.

The Hydroset system in Sandvik cone crushers provides both safety and setting adjustment functions. It incorporates a heavy-duty hydraulic cylinder that supports the mainshaft and adjusts its position. The system also offers automatic overload protection, allowing the mainshaft to drop and permit the passage of tramp iron or other uncrushable materials. The system then automatically returns the mainshaft to its original position, ensuring smooth and uninterrupted operation.

Sandvik cone crushers are designed with ease of maintenance in mind. All service and inspection tasks can be carried out from above, making maintenance easier and reducing downtime. The robust sealing to the inner crusher mechanics provides effective protection against dust and other unwanted particles, further reducing maintenance needs and increasing the crusher's lifespan. The ASRi system not only optimizes production but also tracks liner wear, making it easy to plan liner changes and minimize production interruptions.

In addition to their high capacity, Sandvik CS and CH crushers are compact, making them easy to move and install. This flexibility, combined with their robust design and high performance, makes Sandvik cone crushers a top choice for crushing operations in the mining, construction, and mineral processing industries.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD