ZJ(AH)hard metal/rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive , high density or erosive slurries.

Extra thick sections at wear point and perfect Impeller structure ensures satisfactory performance with long life, and needs minimum maintenance requirements.

Rubber lined pump expand applications to chemical products handling, several different rubber options are available to meet different application needs.

Especially fit in aggressive applications like mill discharge,tailing transportation.

Minerals Flotation Processing

Electric Factory Coal Preparation

Coal Washing

Chemical Medium Processing

Effluent Handling

Sand And Gravel Handling

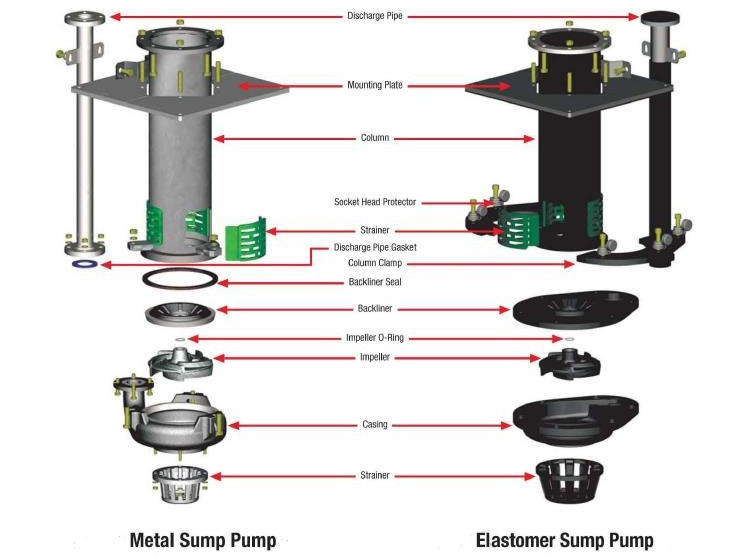

ZJL(SP)Series slurry pumps are designed for handling abrasive and corrosive slurries whilst submerged in sumps or pit. The pump has no shaft seal, easy to maintenance and cost less. Hard metal and rubber parts are optional for different applications and interchangeable. Suit for most applications where sump slurry pumps are needed.

Sump drainage washdown

Floor drainage

Mill sumps

Carbon transfer

Monitoring

Magnetite mixing

ZJH(HH)Series Pump are designed for heavy duty applications require high head per stage at high pressures, suitable for long distance transporting or where other applications require more than one pump in series. The range is capable of handling medium size particles and pumping at heads in excess of 90 meters per stage.

Tailings Delivery

Cyclone Feed

Diamond Concentrate

Slag Granulation

Bottom Boiler and Fly Ash

Mill Discharg

ZJD(L) Low to Medium Head Slurry Pumps WL hard metal light to medium duty slurry pumps are designed for continuous slurry handling applications where a large flow at a low to medium head is required. Especially for medium abrasive and lower solids concentrations applications. Similar in structure to ZJ pump pumps are smaller sized and relatively economical to handle mild slurries.

Electric Factory Coal Preparation

Coal Washing

Chemical Medium Processing

Effluent Handling

Salt and Sugar Industry

Sand And Gravel Handling

Thickener & Tailings

Power Generation

Mineral Processing (coal, copper, gold, iron ore, nickel, oil sands, phosphate)

ZJS(G) pump are designed for continuous pumping of highly abrasive slurries that containing large particles which other NaiPu pumps can not handle, Large passage inside casing make it the best choice for gravel, dredging and other applications where large particles needed to be handled, especially for big flow, high concentration, high head media. Low NPSH requirement and robust design ensures long life under severe duties.

Slag Granulation

Suction Hopper Dredging

Dredging

Barge Loading

Sand Reclamation

The Pump can be drived by motor or diesel engine.

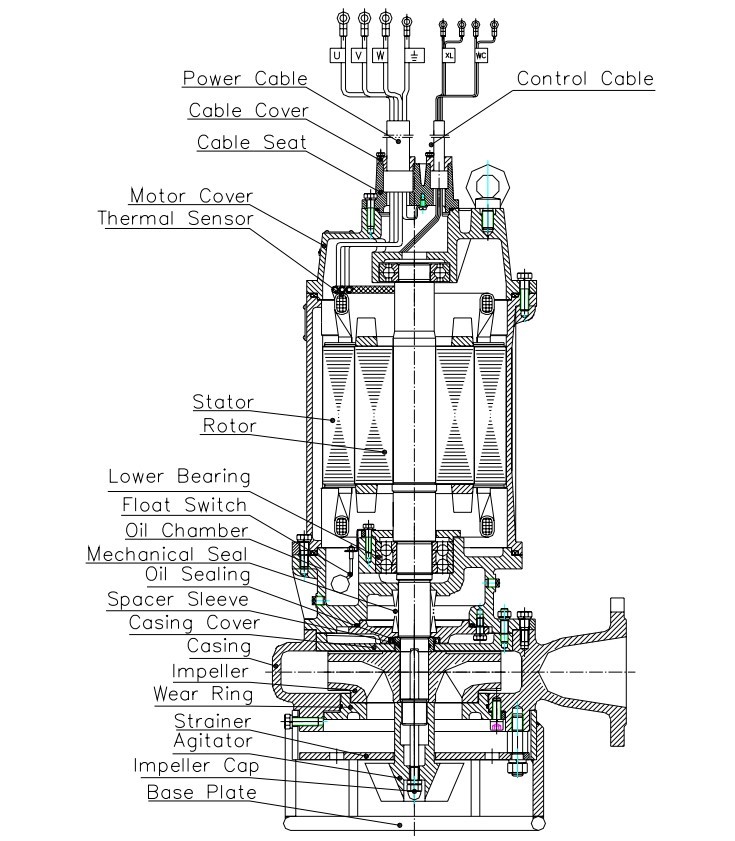

ZJQ submersible slurry pump is the hydraulic machinery with coaxial motor and water pump and submerge in the medium for work. The product has excellent material selection, advanced structure, wide flow channel and strong corrosion resistance.

It is suitable for conveying the liquid with sandstone, coal cinder, tailings and other solid particles.

It is mainly used for cleaning and conveying of the slurry liquid of metallurgy, mine,

Thermal power plant and other enterprises, and is the ideal substitute product of the traditional slurry pump.

The series products are designed and manufactured by absorbing the foreign advanced technology. A set of mixing impeller is added at the bottom at the water pump except for the primary impeller, which can spray the sedimented sludge to eddy flow, so that high concentration convey can be realized when the water pump has no auxiliary device.

The unique sealing device can effectively balance the pressure inside and outside the oil chamber, so that pressure at both ends of mechanical seal is maintained balanced. It guarantees operation reliability of mechanical seal to the maximum limit, and greatly extends the service life.

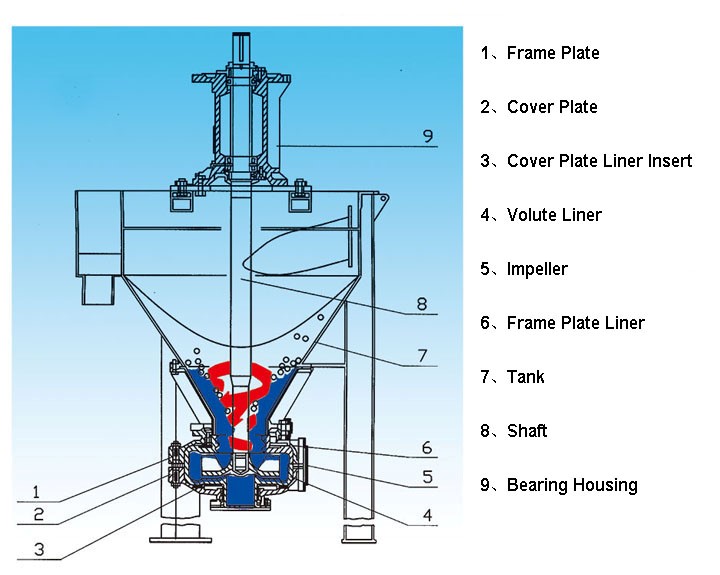

NVF Series Froth Pumps are the latest generation of froth pump based on advanced technology at home and abroad.It is designed to pump frothy slurries more efficiently by de-aerating or partially de-aerating the froth ,by an induced vortex principal,before it enters the pump head.

It is double casing vertical pump complete with hopper.It features a wide choice of replaceable abrasion resistant metal or moulded rubber casing liners and impellers.The hopper-tank is fabricated with steel plate. Its inner wall of the tank can be covered with liner according to different medium pumped.

Iron Ore Dressing Plant

Copper Concentration Plant

Gold Mine Concentration Plant

Molybdenum Concentration Plant

Potash Fertilizer Plant

Other Mineral Processing Plants

Other industries

NHF series froth pumps are heavy duty horizontal pumps designed to handle heavy froth slurries. The large oversized inlet with unique impeller Induced vane makes it easy to handle heavy froth and high viscosity dense slurries. The pumps are very valuable for very dense slurries where viscosity begins to become a pumping issue for standard slurry pumps.

Iron Ore Dressing Plant

Copper Concentration Plant

Gold Mine Concentration Plant

Molybdenum Concentration Plant

Potash Fertilizer Plant

Other Mineral Processing Plants

Other industries

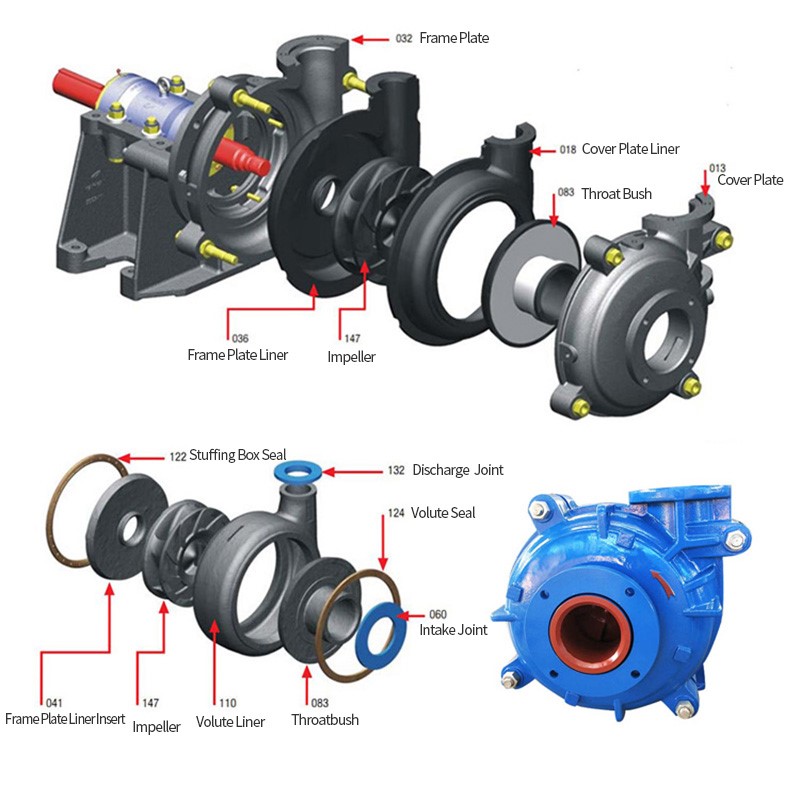

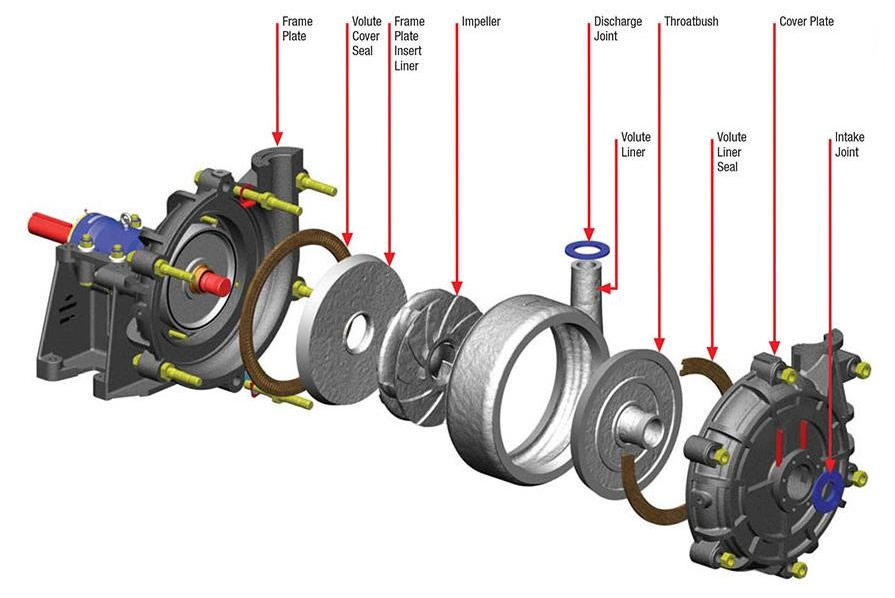

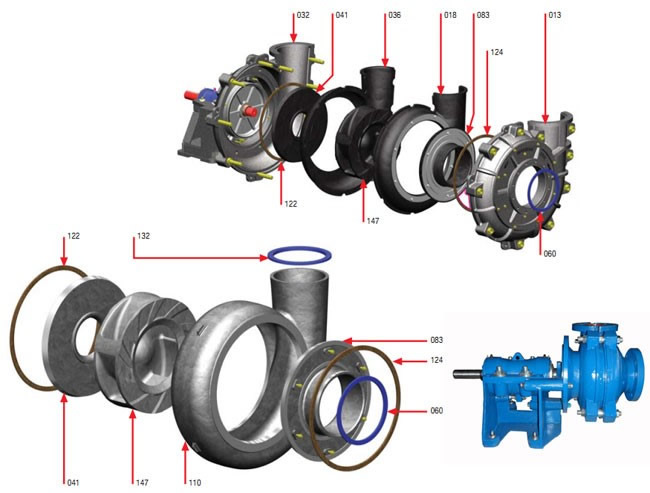

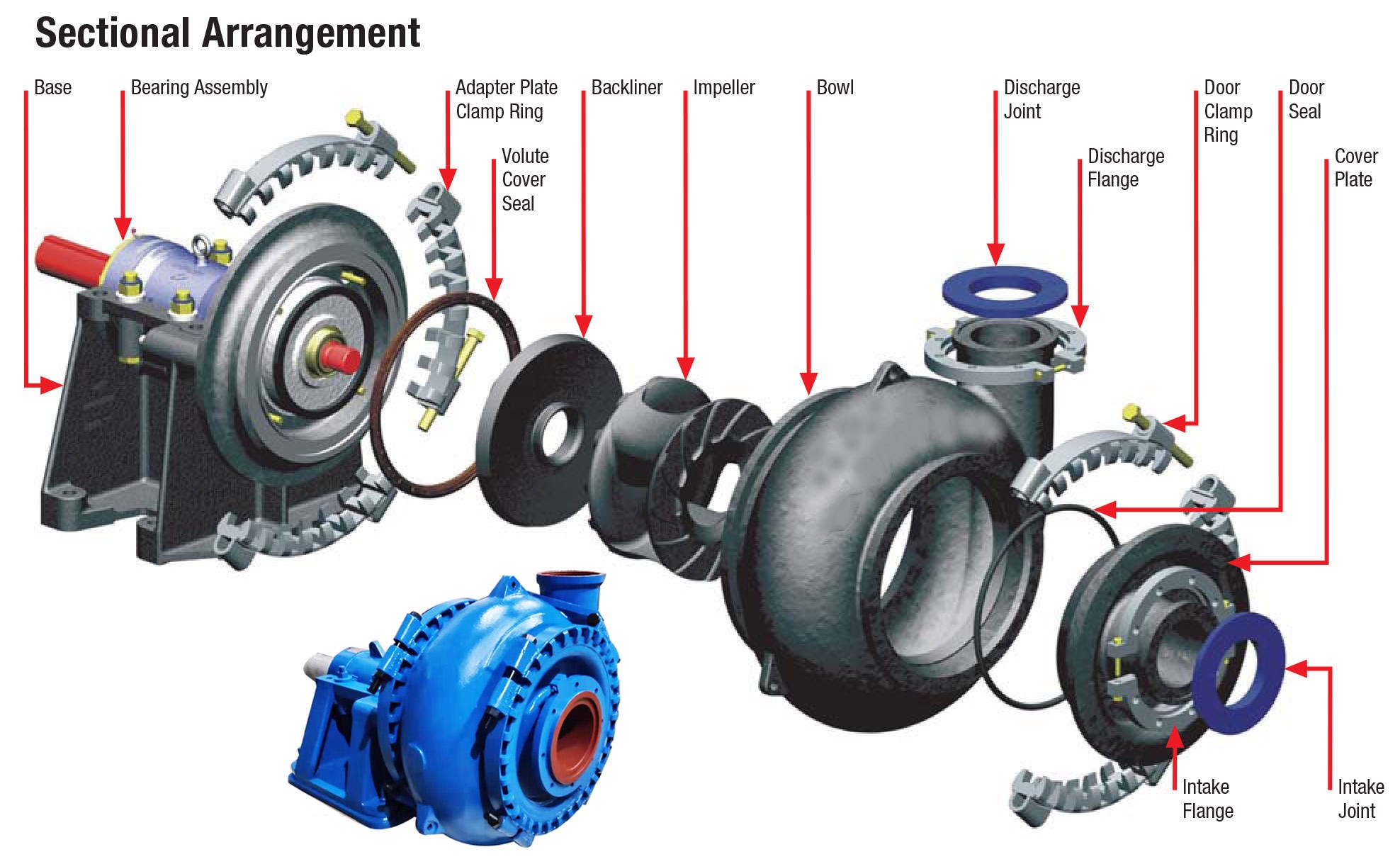

Standard pump spare partscan be totally 100% interchange with AH HH M L SP AF G Series.

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD