Outer and inner bushings are critical components in the operation of Krupp KB series gyratory crushers. These bushings play a vital role in ensuring the smooth and efficient functioning of the crusher by providing support and reducing friction between moving parts. Below is a detailed explanation of their design, function, and importance in the overall performance of the crusher.

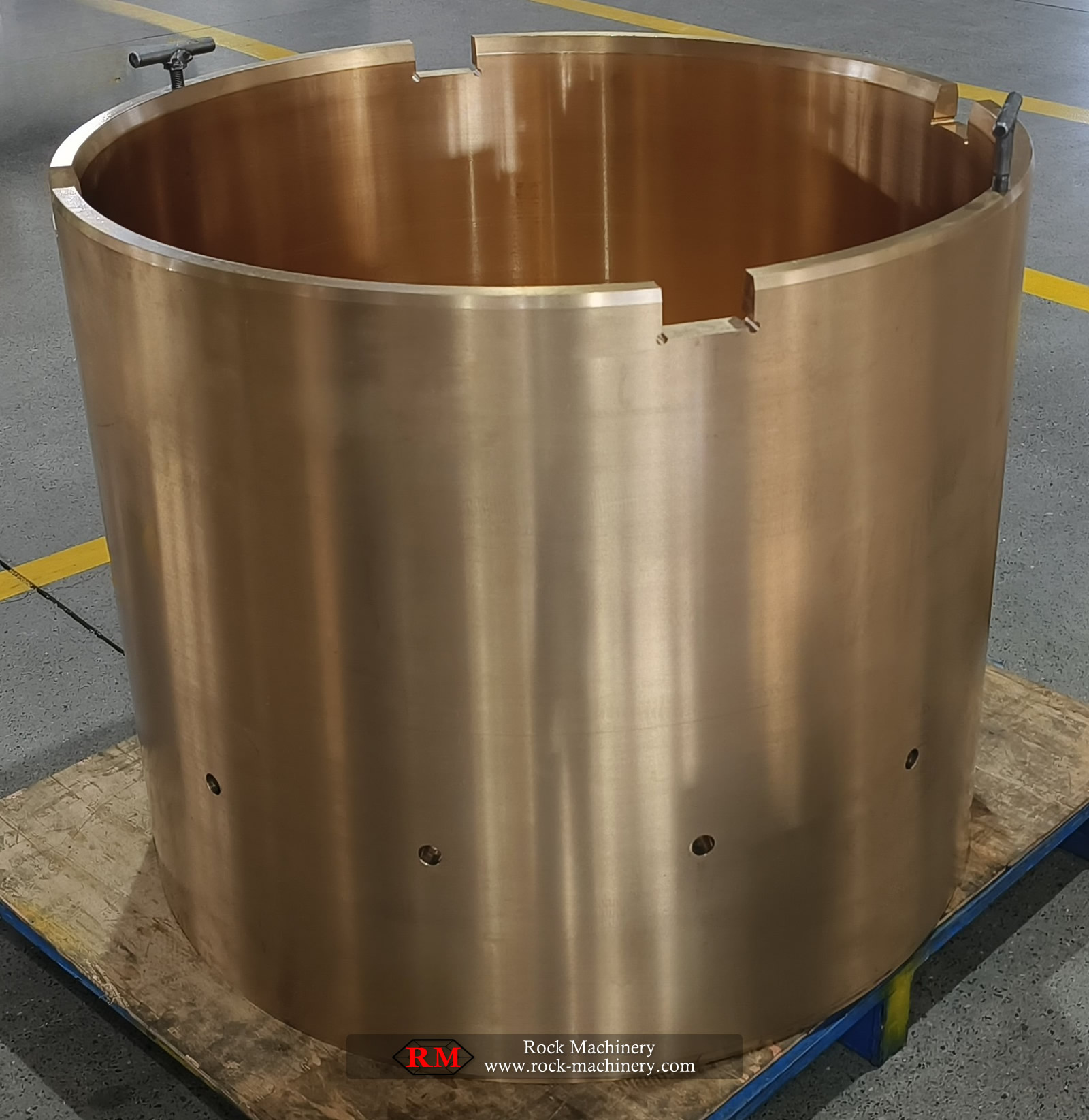

The outer bushing, also known as the eccentric bushing, is a key component located in the lower part of the crusher. It is mounted within the outer eccentric bushing housing and is responsible for guiding the main shaft's eccentric motion. The outer bushing is designed to withstand high loads and stresses, ensuring the crusher's stability and durability during operation.

Key features of the outer bushing include:

1. Material Composition: The outer bushing is typically made from high-quality, wear-resistant materials such as bronze or other specialized alloys. These materials are chosen for their ability to withstand the extreme pressures and abrasive conditions encountered in crushing operations.

2. Precision Engineering: The outer bushing is precision-engineered to ensure a perfect fit within the crusher's housing. This precision is crucial for maintaining the correct alignment of the main shaft and ensuring smooth, efficient operation.

3. Lubrication: Proper lubrication is essential for the outer bushing's performance. The crusher's oil circulating lubrication system ensures a continuous supply of lubricant to the bushing, reducing friction and wear, and extending its service life.

4. Maintenance: Regular inspection and maintenance of the outer bushing are necessary to ensure its optimal performance. This includes checking for wear and tear, ensuring proper lubrication, and replacing the bushing when necessary to prevent unexpected downtime.

The inner bushing, also known as the spider bushing, is located in the upper part of the crusher, within the spider assembly. It supports the main shaft and allows it to rotate smoothly, facilitating the crushing process. The inner bushing is subjected to significant radial and axial loads, making its design and material composition critical to the crusher's performance.

Key features of the inner bushing include:

1. Material Composition: Similar to the outer bushing, the inner bushing is made from high-quality, wear-resistant materials. These materials are selected for their ability to endure the high stresses and abrasive conditions present in the crushing chamber.

2. Precision Fit: The inner bushing is designed to fit precisely within the spider assembly, ensuring proper alignment and smooth rotation of the main shaft. This precision fit is essential for maintaining the crusher's efficiency and preventing premature wear.

3. Lubrication: The inner bushing is lubricated by the crusher's grease lubrication system. This system ensures a continuous supply of grease to the bushing, reducing friction and wear, and prolonging its service life.

4. Maintenance: Regular maintenance of the inner bushing is crucial for the crusher's performance. This includes checking for wear, ensuring proper lubrication, and replacing the bushing when necessary to avoid operational issues.

Both the outer and inner bushings are integral to the efficient operation of Krupp KB series gyratory crushers. They provide critical support to the main shaft, ensuring smooth and stable rotation, which is essential for effective crushing. The use of high-quality materials and precision engineering in the design of these bushings ensures their durability and reliability, even under the most demanding conditions.

Regular inspection and maintenance of the bushings are essential to prevent unexpected failures and downtime. By using our high-quality replacement bushings, you can ensure the continued performance and longevity of your Krupp KB series gyratory crushers, maintaining high productivity and minimizing operational costs.

We take pride in manufacturing our outer and inner bushings in-house, ensuring the highest standards of quality and precision. Our production process strictly adheres to the original ThyssenKrupp design specifications and drawings, guaranteeing that every bushing we produce is an exact match for the original equipment. This commitment to precision and quality ensures that our bushings deliver the same performance and reliability as the original parts.

Our state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, allowing us to produce bushings that meet the exacting demands of the mining and aggregates industries. Our team of skilled engineers and technicians meticulously oversee every stage of the production process, from material selection to final inspection, ensuring that each bushing meets our stringent quality standards.

By choosing our bushings, you can be confident that you are receiving parts that are not only manufactured to the highest standards but also fully compatible with your Krupp KB series gyratory crushers. Our commitment to quality and precision ensures that your crushers will continue to operate at peak performance, minimizing downtime and maximizing productivity.

In summary, the outer and inner bushings are vital components that contribute significantly to the overall performance and reliability of Krupp KB series gyratory crushers. Their design, material composition, and maintenance are crucial factors in ensuring the efficient and continuous operation of these powerful crushing machines. With our in-house manufacturing and adherence to original specifications, we provide bushings that you can trust to keep your crushers running smoothly and efficiently.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD