[Product application]

Symons cone crusher 2ft ~ 7ft. Metso cone crusher HP3 ~ HP6. Metso cone crusher HP100 ~ HP800. Metso cone crusher GP11 ~ GP550. Metso MK Gyratory crusher S42-65 ~ S60-110. Metso MP800, MP1000, MP1250, MP2500. Sandvik cone crusher CH420 ~ CH890. Sandvik cone crusher CS420 ~ CS660. Minyu MCC40, MCC45, MCC51, MCC54, MCC60, MCS200, MCS300. Nordberg OMNICONE 937, 1144, 1352, 1560.

[Product Material]

C93800, C93700, JM 14-15, CuPb15Sn7, CuPb20Sn5.

[Product technology]

Centrifugal casting.

[Product features]

Replace the original part directly.

All products are rigorously inspected for defects and fully meet work standards.

Dimensions 100% same as original part.

[Product application]

Symons cone crusher 2ft ~ 7ft. Metso cone crusher HP3 ~ HP6. Metso cone crusher HP100 ~ HP800. Metso cone crusher GP11 ~ GP550. Metso MK Gyratory crusher S42-65 ~ S60-110. Metso MP800, MP1000, MP1250, MP2500. Sandvik cone crusher CH420 ~ CH890. Sandvik cone crusher CS420 ~ CS660. Terex TC1000, MVP380, MVP450, MVP550. Minyu MCC40, MCC45, MCC51, MCC54, MCC60, MCS200, MCS300. McCloskey MC200, MC300, MC400, . Nordberg OMNICONE 937, 1144, 1352, 1560.

[Product Material]

Mn13Cr2, Mn18Cr2, Mn21Cr2, Mn21Cr2Mo, XT510, XT520, XT610, XT710, XT720.

[Product technology]

Sand casting.

[Product features]

Replace the original part directly.

All products are rigorously inspected for defects and fully meet work standards.

Dimensions 100% same as original part.

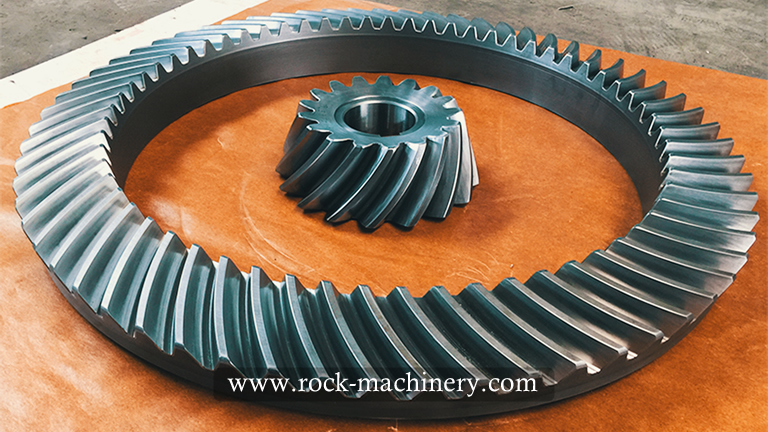

[Product application]

Symons cone crusher 2ft ~ 7ft. Metso cone crusher HP3 ~ HP6. Metso cone crusher HP100 ~ HP800. Metso cone crusher GP11 ~ GP550. Metso MK Gyratory crusher S42-65 ~ S60-110. Metso MP800, MP1000, MP1250, MP2500. Sandvik cone crusher CH420 ~ CH890. Sandvik cone crusher CS420 ~ CS660. Minyu MCC40, MCC45, MCC51, MCC54, MCC60, MCS200, MCS300.

[Product Material]

20CrMnTi, 18CrNiMo7, 42CrMo4, 50CrMo4.

[Product technology]

Grinding Gear.

[Product features]

Replace the original part directly.

All products are rigorously inspected for defects and fully meet work standards.

GLEASON gear.

Dimensions 100% same as original part.

[Product application]

Metso jaw crusher C63 ~ C200. Terex JW40, JW42, JW55. McCloskey jaw crusher J40, J44, J45, J50. Sandvik jaw crusher CJ208 ~ CJ815.

[Product Material]

Mn13Cr2, Mn18Cr2, Mn21Cr2, Mn21Cr2Mo, XT510, XT520, XT610, XT710, XT720.

[Product technology]

Sand casting.

[Product features]

Replace the original part directly.

All products are rigorously inspected for defects and fully meet work standards.

Dimensions 100% same as original part.

[Product application]

Symons cone crusher 2ft ~ 7ft. Metso cone crusher HP3 ~ HP6. Metso cone crusher HP100 ~ HP800. Metso cone crusher GP11 ~ GP550. Metso MK Gyratory crusher S42-65 ~ S60-110. Sandvik cone crusher CH420 ~ CH890. Sandvik cone crusher CS420 ~ CS660. Minyu cone crusher MCC40 ~ MCC60. Metso jaw crusher C63 ~ C200. Minyu MCC40, MCC45, MCC51, MCC54, MCC60, MCS200, MCS300. Sandvik jaw crusher CJ208 ~ CJ815.

[Product Material]

1045 steel, 42CrMo, 42CrMo4.

[Product technology]

Forging.

[Product features]

Replace the original part directly.

All products are rigorously inspected for defects and fully meet work standards.

Dimensions 100% same as original part.

[Product application]

Symons cone crusher 2ft ~ 7ft. Metso cone crusher HP3 ~ HP6. Metso cone crusher HP100 ~ HP800. Metso cone crusher GP11 ~ GP550. Metso MK Gyratory crusher S42-65 ~ S60-110. Sandvik cone crusher CH420 ~ CH890. Sandvik cone crusher CS420 ~ CS660. Minyu cone crusher MCC40 ~ MCC60.

[Product Material]

20Mn5.

[Product technology]

Sand casting.

[Product features]

Replace the original part directly.

All products are rigorously inspected for defects and fully meet work standards.

Dimensions 100% same as original part.

Heavy-duty machines designed for primary and secondary crushing operations in mining, quarrying, and construction industries.

Utilize a conical crushing chamber with a rotating cone that crushes material against a fixed bowl liner.

Produce high-quality, cubical-shaped aggregate with a narrow size distribution.

Available in various sizes and capacities, from small mobile units to large stationary installations.

Primary crushers widely used in mining, quarrying, and recycling operations.

Feature two opposing jaws, one fixed and one moving, that crush material by compression.

Produce coarse, angular aggregate suitable for road construction and other applications.

Available in various sizes and jaw configurations, accommodating different feed sizes and capacities.

Essential components for maintaining the performance and longevity of cone and jaw crushers.

Include wear parts (e.g., bowl liners, mantles, jaw plates, toggle plates), drive components (e.g., shafts, gears, bearings), and hydraulic components (e.g., cylinders, pumps, valves).

Manufactured using high-strength materials and designed to withstand extreme operating conditions.

Regular replacement of wear parts extends crusher life and optimizes production efficiency.

ZHEJIANG ROCK MACHINERY CO., LTD

Registered in China

Registration number: 91330782MACQ9CX477

Focus on ore processing machines

Leader of aftermarket mining parts

Over 20 years of specialized experience

Full parts support

Fast delivery and quick response

Sales representative:

Tel:

WhatsApp:

WeChat:

Complaints and suggestions

©2026 ZHEJIANG ROCK MACHINERY CO., LTD